Construction

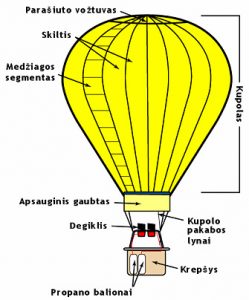

THE DOME

The dome of the hot air balloon is sewn from high-strength nylon materials – polyester or polyamide, the inner side of which is covered with polyurethane (silicone). Polyurethane coating makes the fabric airtight. To make the material stronger, it is woven with a compacted mesh of yarn strips.

Pieces of material – segments – are sewn into columns, which are then sewn together. The dome inflation opening is lined with a strip of protective material Nomex, which is highly heat resistant and protects the dome from burns during inflation.

Further, vertical and horizontal load strips are sewn on the dome. The number of both lanes varies depending on the number of lobes and the shape of the dome. The more sections the balloon has, the more sewing strips, the weaker they can be. At the top, the straps are attached to the top ring, and at the bottom of the dome, below the bottom rim, the strap is connected to the dome suspension ropes. The joints are hidden in bags made of Nomex material. This results in a solid dome frame.

Domes are classified according to their volume and lifting capacity, i.e. the maximum weight that the dome can lift.

BURNERS

Figuratively speaking, the burners are a hot air balloon power plant. This is the most mechanically difficult part of the air balloon. The burners heat the air by blowing the balloon and maintaining the temperature during the flight. The burners are “powered” by liquid propane, which is gasified before burning in the burner coils. Therefore, almost half of the burner consists of a spiral. Liquefied gas enters the burner from a gas cylinder. In a spiral, liquid propane is heated, and when heated, it turns into gas. A hot burner works more efficiently than a cold one. Modern burners come with protective boxes that protect the pilot’s hand from burns and trap the heat from the hot burner down. The burner is made of very strong stainless steel, as the combustion temperature of propane is about +500 C. So the burners have to withstand very large differences in temperature. Modern balloon burners are very powerful – they have a capacity of 4500-6000 megawatts.

THE BASKET

The bags are usually made of wicker, the bottom of the bag is made of moisture-resistant sea plywood. 6 mm stainless steel ropes are used for the structural basket frame. They attach the bag to the dome. Polyurethane stands are inserted into the sockets of the basket frame and the burner frame. They strengthen and make a stable heating system. These racks and ropes are covered with leather sheaths that protect the racks and ropes from mechanical damage. Gas cylinders are usually fastened with leather straps at the corners of the bag. Appliances, a map case, a fire extinguisher and other accessories are also attached to the bag in their designated places.